cheese vat for sale

100-10,000 Liter per hour cheese vat cheese making machine mozzarella cheese making machine

Product description

Video

Description

100-10,000L Cheese Making Vat for Sale

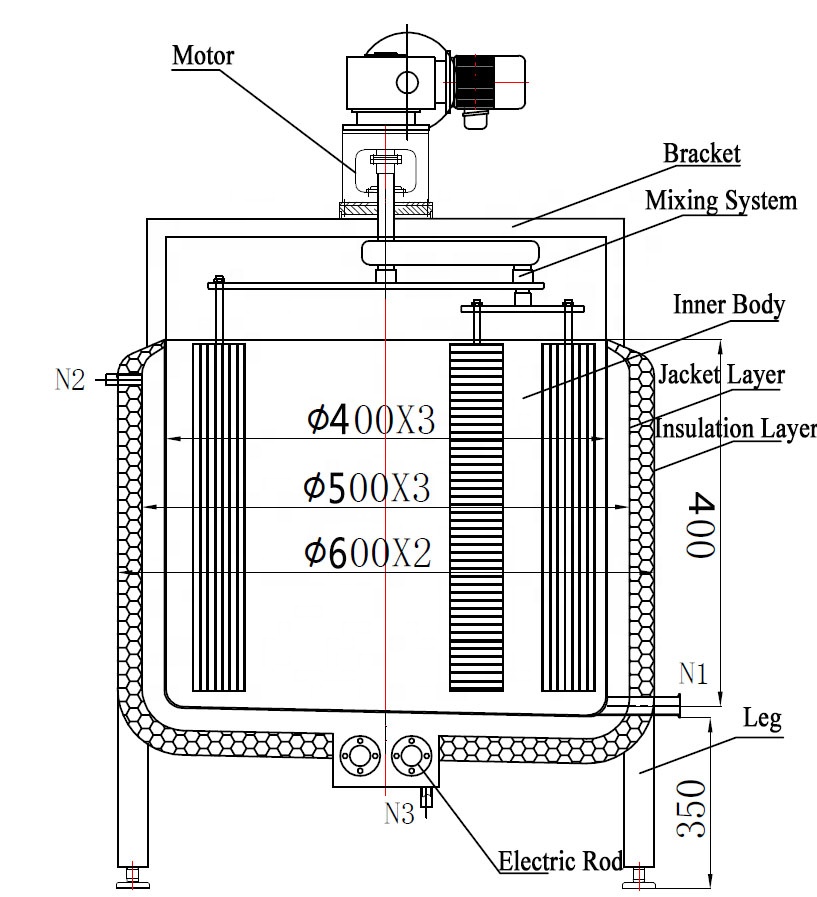

This cheese vat consist of a triple-walled, insulated, oblong or round stainless steel vat with an overhead stirring machine.

The stirring mechanism of oblong vat is driven by two motors: one for longitudinal move and one for the rotating motion.

The control panel is fitted into the superstructure. By means of the ‘touch screen‘ on this panel various programs for stirring,

cutting and tipping can be executed.

All programs are automatically controlled by a PLC that operates the various drive components. It is controlled the accurtelt

temperature of mlik in vat by an electrical thermostat system to operate the steam valve heating water.

The oblong cheese vat is fitted with a fully automatic process controller. This controller allows programs for a range of

processes for the production of types of cheeses to be stored and executed. This helps ensure uniform cheese quality.

The capacity of this cheese vat from 100 Liters to 10000 Liters depend on the requirement from the customer.

1)If the volume≥4000L, the cheese vat has two stirring devices for longitudinal and rotating motion ,

the stirring speed can be adjusted stepless.

If the volume ≤4000L, the cheese vat has only one stirring device

2)The cheese vat has temperature control system to control the temperature of jacket water and the curd

3)Sanitary outlet with outlet valve is equipped with this cheese vat. A lift device by a cylinder is set in one

head of this cheese vat to incline this cheese vat to drain the whey easily

4)Cheese vat with a volume ≤ 3000L can equipped with cheese press machine or net- cutting

5)The material is stainless steel 304 or 316L

Working principle:

The machine is composed of vat main body, cutting knife, agitator blade, etc. Through manual control, milk filling, ingredient mixing, milk coagulation, whey cutting, heating and cooling are realized. It is suitable for curd processing most cheese.

Vat with a heating sandwich can achieve pasteurization and cooling of milk, and can quickly cool milk by connecting cooling water.

At the same time, vat is equipped with a temperature control box, which can accurately control the temperature. Under certain temperature conditions, milk is fermented in vat, or milk curds by adding chymosin.

The machine is equipped with a curdling knife to cut curdling into small pieces of uniform size, so that whey can be discharged easily. The equipment is equipped with manual hydraulic support, which can support one side to facilitate whey evacuation. After the whey is discharged, the whey in the curd tank is emptied and cleaned, so that cheese can be produced again.

Structural composition:

Vat, cutting blade, mixing blade, electro-empty cabinet, leg, whey discharge pipe and so on.

Vat is made of high quality stainless steel.

You Might Also Like

Send Inquiry Our expert salesman will get back to you within 24hours!!!