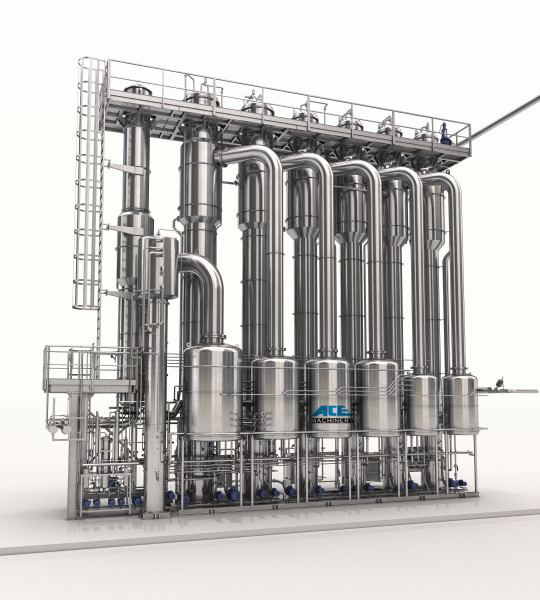

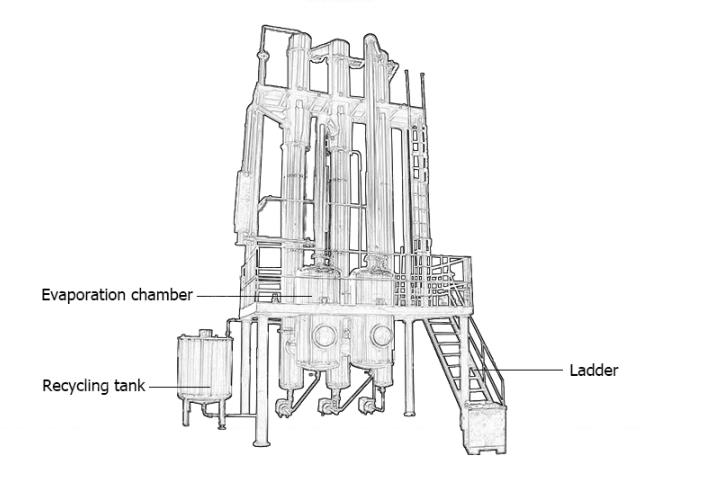

Double effect falling film evaporator

High Quality Double Effect Falling Film For Tomato And Milk Syrup Evaporator

Product description

Video

Description

It is especially suitable for heat sensitive products. With the function of continuous feeding and discharging, the fall film concentrator is stable and easy to operate. When the system starts to work, it only needs to adjust various parameters as required in the initial feeding stage and ensure continuous and stable supply of materials at the same time, then it can concentrate the product continuously, stablely, efficiently to reach qualified gravity requirements. The solvent can be recovered at the same time. We can design and produce it as one effect type, two effect type and three effect type according to the different requirements of different customers. The more effects, the more energy saving. The whole system of the fall film concentrator can be automatically controlled by PLC.

Products features

1.Because of the whole equipment uniform heating steam heating system, material liquid to liquid film flow evaporation, so it has high heat transfer efficiency, short heating time ,etc major features. If relocation thermal compression pump, more energy saving, low steam consumption and low cooling water circulation.

2.The material flow accelerated down the tube wall pressure evaporation, adapt to the larger material liquid viscosity evaporation concentration.

3.Because the material in each tube formed into membrane evaporation and material liquid heating time is very short, so evaporation and concentration is very good, especially for food larger preserve the nutrition of the food.

4.Under vacuum evaporation process, not only ensure the material requirement, also ensure the requirements of environmental protection, at the same time, greatly reduces the evaporation temperature, plus configuration thermal compression pump, part of the secondary steam by thermal compression pump suction again and raw mix, saves the steam, at the same time by thermal compression pump heating steam spray fog shaped into the shell, steam quickly spread, material liquid heating slowly, so the suitable concentration of thermal sensitive material.

5.Equipment is suitable for evaporation and concentration of foam materials , due to the material liquid into membrane evaporation in the heating tube, which form the gas-liquid separation,at the same time, most of the material liquid at the bottom of the body is siphoned off, only a small part of the material liquid into separator separation, the whole process of material liquid forming no too big impact, greatly reduce the formation of bubbles.

6.For food, evaporating equipment can have sterilization function at the same time, the material after preheating first, and then into the sterilizer, reach more than 94 degrees, hold on 24 seconds, which entered 1st -effect , rapid flash of material,temperature in an instant.

7.Equipment equip with CIP clean system, realize the in-place cleaning, the the whole set of equipment is easy to operate, no dead Angle.

8.Design continuous feeding and discharging.

9.Equipment can equip with automation system, can be configured to realize automatic feed rate control, the heating temperature automatic control, automatic discharging concentration control, automatic cleaning control, can also be equipped with a sudden power failure, failure protection for sensitive material. Other safety, alarm and other automation control.

Range of application

Suitable for evaporation concentration is lower than the saturation density of salt material, and heat sensitive, viscosity, foaming, concentration is low, liquidity good sauce class material. Especially suitable for milk, glucose, starch, xylose, pharmaceutical, chemical and biological engineering, environmental engineering, waste liquid recycling etc for evaporation and concentration, low temperature continuous has high heat transfer efficiency, shorter time for heating the material, etc main features.

Evaporation capacity: 1000-60000kg/h(Series)

In consideration of each factories all kinds of solutions with different characteristics and complexity, our company will provide specific technical scheme according to client’s requirements, reference for users to choose!

You Might Also Like

Send Inquiry Our expert salesman will get back to you within 24hours!!!