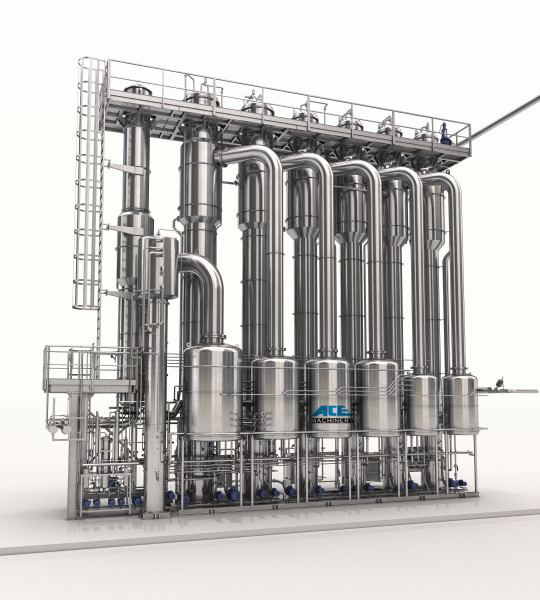

Forced Circulation Evaporator - An Efficient and Flexible Solution

A forced circulation evaporator is the best choice for your business because it is more efficient than a natural evaporator It uses less energy and water and is less expensive to operate

Product description

Description

The applied power circulates the forced circulation evaporator, and the pump is used to move the solution to pass through the heating tube at a speed of 2-5 m/s in one direction. Other evaporators are natural circulation movements of the solution due to the difference in density between the heating chamber and the key in the circulation tube. Therefore all belong to the natural circulation type evaporator. Their common shortcoming is that the circulation speed of the solution is low, and the heat transfer effect is not good. A forced circulation evaporator can be used to treat solutions with high viscosity, easy fouling, or crystallization.

It is suitable for evaporation and crystallization of high-concentration, high-viscosity material, and other materials containing insoluble solids.

Overview.

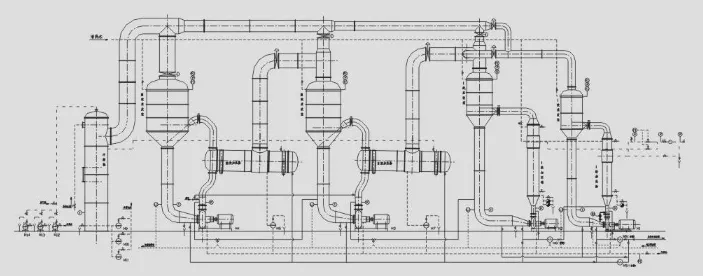

Forced circulation evaporator is the material through the high flow circulation pump to the column tube heater, after heating into the separator evaporation and separation, not evaporated residual material back again by the circulation pump to the heater heating evaporation, to form a repeated cycle evaporation system, widely used in food, pharmaceutical, chemical, environmental protection and other industries of the water phase or organic phase solution evaporation concentration, especially suitable for viscosity, easy It is especially suitable for the evaporation and concentration of considerable consistency, easy scaling and crystalline materials under atmospheric pressure or vacuum conditions, intermittent or continuous evaporation and attention, which can be single- or multi-effect evaporation and concentration.

The second is the scope of use.

The forced circulation evaporator is suitable for treating materials with scaling, crystallization, heat sensitivity (low temperature), high concentration, high viscosity, and insoluble solids with particles. The system consists of

System composition.

Each effect evaporator, effect separator, condenser, circulation pump, transfer pump, vacuum, drainage system, sub-cylinder, operation platform, electrical instrumentation control cabinet and valves, pipelines, and other methods.

Fourth, the characteristics of the equipment.

One 、A complete set of systems with practical and beautiful design, stable operation, high efficiency, energy-saving, and low steam consumption.

Two 、The concentration ratio is large, and the forced circulation type makes it easy for the viscous material liquid to flow and evaporate.

Three 、Special design can be switched to change the efficiency by a simple operation to adapt to the production of different products.

Four 、The evaporation temperature is low, heat is fully utilized, and the liquid is heated mildly, which is suitable for the concentration of low-temperature heat-sensitive materials.

Five 、The evaporator is heated evenly in the tube through forced circulation, and the heat transfer coefficient is high, which can prevent the drywall phenomenon.

Six 、The material liquid enters the separator and separates again, strengthening the separation effect and giving the overall equipment greater operational flexibility.

Seven 、Compact structure of the whole set of equipment, small footprint, simple and smooth layout, easy to clean.

Eight 、Continuous inlets and outlet, the liquid level and concentration of the material can be self-control.

Technical parameters.

Model | ACE-01 | ACE-02 | ACE-03 | ACE-04 |

(t/h) Water Evaporation capacity | 0.5-5 | 0.5-10 | 2-30 | 5-30 |

(%) Input concentration | (According to material) | |||

(%) Output concentration | (According to material) | |||

(Mpa) Steam pressure | 0.2-0.4 | |||

(mmhg) Maximum Vacuum | 650 | |||

(℃) Evaporation temperature | 45-90 | |||

(kg/kg) Steam consumption/Evaporation capacity | 1.2 | 0.65 | 0.40 | 0.37 |

(T/T) Cooling water cost/Evaporation capacity | 32 | 16 | 11 | 9 |

The above parameters are for reference only, and we support customization. | ||||

Working Principle

The circulation of the solution in the equipment mainly depends on the forced flow generated by the applied power. The cycle speed is generally up to 1.5-3.5 m/s. Heat transfer efficiency and production capacity are significant. The raw material liquid is driven from the bottom up by the circulation pump and flows upward in the tube of the heating chamber. After the steam and liquid mixture enters the evaporation chamber, the vapor is separated from the upper part; the fluid is blocked. The circulating pump sucks it through the conical bottom and then enters the heating tube to continue the circulation.

You Might Also Like

Send Inquiry Our expert salesman will get back to you within 24hours!!!