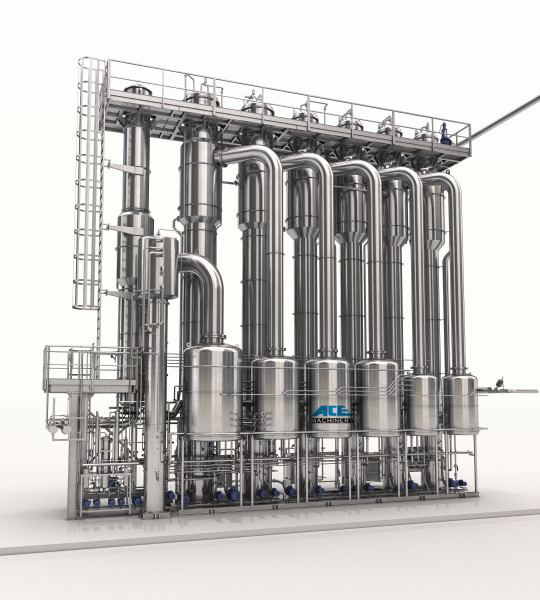

vacuum decompression extraction concentrator

Electric Heating Fruit Juice Vacuum Pressure Reduced Concentrate Machine

Product description

Video

Description

Applicable industry:

The products are mainly suitable for the concentrated production process of industries with high viscosity, Chinese medicine, health products, natural seasonings, food additives, chemical industry and so on.

200L Low Temperature Vacuum Concentrator for herbal extract liquid evaporating machine for juice/milk/pharmacy factory

Working principle:

When the equipment is working, the liquid material enters the heating tube from the bottom of the heater, and the liquid level accounts for about 1/5 to 1/4 of the length of the tube. The steam is heated outside the tube to make the liquid boil and quickly vaporize, and the steam rises in the tube at high speed. The material is squeezed towards the wall of the pipe, and the secondary steam gradually increases from the bottom to the inside of the pipe, so that the material continuously forms a film. Under the induction of the secondary steam and the high vacuum suction of the separator, the concentrated material and the secondary steam are compared. The fast speed enters the separator along the tangential direction. Under the centrifugal force of the separator, the material rotates at a high speed along its peripheral wall and is evenly distributed on the peripheral wall and cone bottom. The surface area of the material liquid increases, which accelerates the further evaporation of moisture. After the secondary steam and its entrained material droplets are further separated by the mist separator, the secondary steam is introduced into the hydraulic jet pump to condense. The separated concentrated liquid descends along the circulation pipe and returns to the bottom of the heater, with the newly added material The liquid mixes by itself, and then enters the heating tube to concentrate. After a few minutes, the concentration of the feed liquid can reach the requirements. Part of the concentrated liquid can be continuously withdrawn at the bottom of the circulation tube, and part of it can be returned to the heater.

Technical parameter:

1. The internal temperature of the evaporator is 55~65 degrees.

2. Internal vacuum of evaporator: -0.08mpa.

3. The equipment is equipped with a central controller, which can linkage control the supporting equipment.

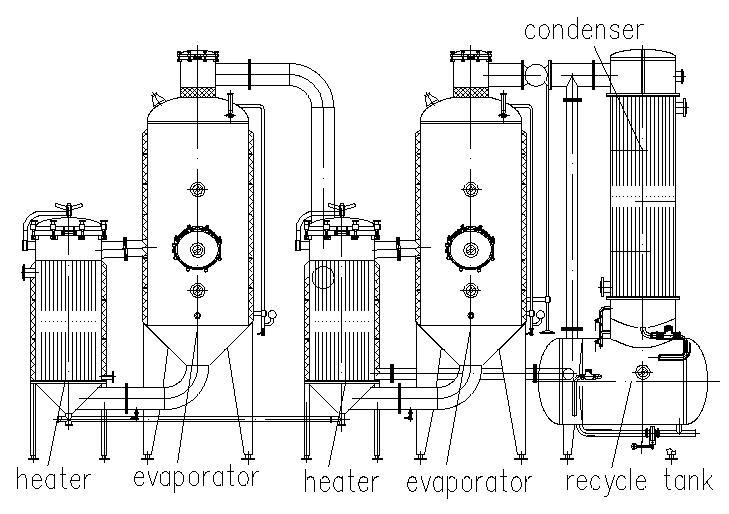

4. All stainless steel material, high vacuum degree, anti-accidental impact.

5. With automatic cleaning system, no need to clean the evaporator manually.

6. Single effect concentration, effective heating area greater than 1/3 of ordinary heater.

7. The whole equipment is vacuum and reduced pressure scraper structure, equipped with tube heater and vacuum evaporator.

8. The centrifugal pump is safe and explosion-proof. After the use of the equipment, the equipment and pipelines can be automatically cleaned with acid, alkali and clean water. All stainless steel structure support equipment is easy to clean and maintain.

9. Special vacuum pump: safety and explosion proof, power: 7.5KW.

10. The equipment evaporator is of cylindrical camber structure, and at the same time, a conical circulatory screw pump is added at the bottom. The material is continuously cycled and concentrated in evaporator. The actual effective evaporation area of the forced circulation evaporator is 1/3 larger than that of the ordinary evaporator.

11. Vacuum degree of rising film concentrator: -0.05~ -0.08mpa, which can ensure high speed concentration of materials at low temperature.(Generally in 45°~80°)

12. The equipment is compact and covers an area of less than 30 square meters.

13. Heating method: electric or steam heating.

14. Equipment structure: The equipment consists of tube heater, single-effect evaporator, condenser, cooler, material circulation pump, feed screw pump, water ring vacuum pump, stainless steel operating table and other components. The equipment is equipped with CIP cleaning system.

Features

1.Wide range of applications, suitable for evaporative concentration, evaporative crystallization or solvent recovery of various industries and various liquid materials;

2. Operation under vacuum negative pressure, low evaporation temperature, especially suitable for heat-sensitive materials;

3. The stirring device effectively avoids the sticking of the material liquid due to excessive concentration. The high-quality mechanical seal is used to ensure that there is no air leakage due to high vacuum; the special stirring device of the concentration tank is beneficial to accelerate the evaporation rate, Improve the concentration ratio, which is conducive to collecting ointment or crystallization;

4. More suitable for pilot production or laboratory use in small batch production enterprises;

5. The equipment can be operated under negative pressure or normal pressure, and can also be produced intermittently or continuously;

6. It integrates multiple functions such as heating, stirring, liquid mixing, atmospheric evaporation, vacuum concentration, vacuum degassing, condensation recovery, etc., and has strong versatility;

7. The equipment is made of high-quality stainless steel, which is corrosion-resistant, clean and hygienic, without dead corners, and meets GMP requirements;

8. Other components such as vacuum pumps are selected from high-quality brands to ensure the stability and reliability of the entire vacuum system;

9. The heating mode of the equipment can be designed as steam heating or electric heating according to the user's working conditions, to meet the needs of users without boiler heat sources. The high-temperature insulation layer can effectively insulate and reduce heat consumption, effectively reduce energy consumption, and effectively prevent the operator from being scalded.

10. The overall structure is compact, stable performance, simple operation, easy to clean, beautiful and ornamental.

Advantages of vacuum concentration equipment for juice/milk/pharmacy factory

Vacuum concentration equipment is to heat the feed liquid by indirect steam heating under the low pressure state of 18~8kPa, so that it boils and evaporates at low temperature. Vacuum concentration equipment is widely used in food, chemical, pharmaceutical and other industrial sectors, and its main advantages include:

It can reduce the boiling point of the material, accelerate the evaporation of moisture, and avoid high-temperature treatment of the material, which is conducive to preserving the nutritional content of the material; for example, milk at 101kPa, the boiling point is 100 ℃, and at a vacuum of 82.7 ~ 90.6KPa, the boiling point is only 45~55℃. The liquid substance evaporates quickly when the liquid substance is boiling, and its boiling point changes due to pressure. The pressure increases, the boiling point increases, the pressure is small, and the boiling point decreases. At the same time, because the material is not affected by high temperature, the destruction and loss of thermally unstable components are avoided, and the nutritional ingredients and aroma of the raw materials are better preserved. In particular, certain amino acids, flavonoids, phenols, vitamins and other substances can be prevented from being destroyed by heat. For some sugars, proteins, pectin, mucilage and other viscous materials, low temperature evaporation can prevent the material from coking;

By increasing the temperature difference between the heating steam and the material, increasing the heat transfer of the equipment per unit area and time, accelerating the concentration process and enhancing the production capacity;

Low-pressure steam can be used as heating steam to reduce heat loss. The disadvantage of the vacuum concentration equipment is that the concentration requires a vacuum system to increase the auxiliary mechanical equipment and power; because the latent heat of evaporation increases with the decrease of the boiling point, the heat consumption is large.

Classification of vacuum concentration equipment

There are many forms of vacuum concentration equipment, generally classified according to the following method according to the number of times the heating steam is used can be divided into single-effect vacuum concentration equipment and multi-effect vacuum concentration equipment. In the concentration process, the steam generated by the vaporization of the liquid is called secondary steam.

The single effect is that the secondary steam is no longer used as a heat source and directly enters the condenser to condense. It is widely used in small and medium-sized jams, milk powder and condensed milk plants.

Multi-effect is that several evaporators are connected, and the secondary steam generated by the previous concentrator is used as the heating steam of the next concentrator, which is used multiple times. Taking the steam-heated evaporator as the first effect, the evaporator heated by the secondary steam generated by the first effect as the second effect, and so on. The multi-effect concentration equipment of food processing plants generally adopts double-effect and triple-effect. The more effects, the more conducive to energy saving, but the higher the equipment investment cost;

According to the flow of liquid materials, it can be divided into circulating concentration equipment and single-pass concentration equipment. Circulating concentration equipment is divided into natural circulation concentration equipment and forced circulation concentration equipment.

According to the distribution state of the liquid evaporation, it is divided into thin film concentration equipment and non-membrane concentration equipment. When the material liquid in the thin film concentration equipment evaporates, it is dispersed into a thin film in the evaporator.

Single Effect Evaporating Concentrator

Double effect external circulation vacuum concentrator

Three effect external circulation vacuum concentrator

You Might Also Like

Send Inquiry Our expert salesman will get back to you within 24hours!!!