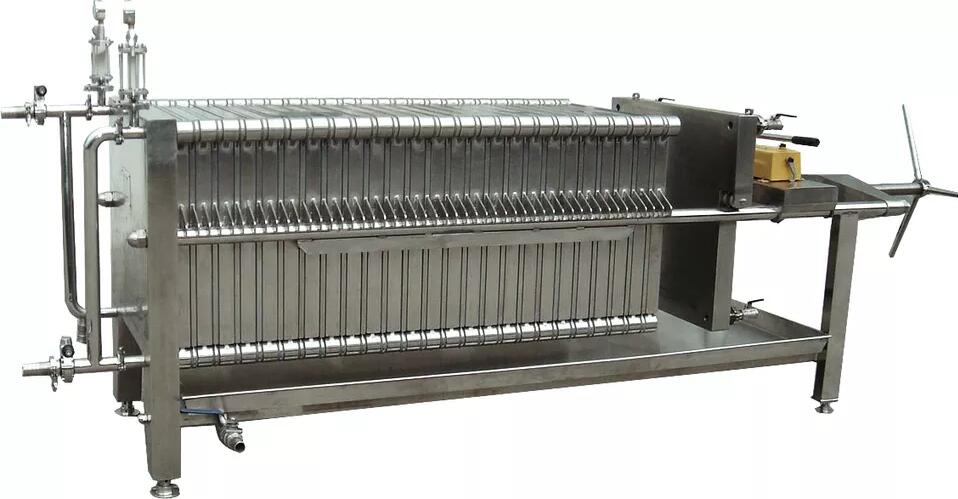

plate and frame filter for beer

The stainless steel plate and frame filter is made of stainless steel with high temperature resistance It is suitable for filtering beer, red wine and other liquids

Product description

Video

Description

The stainless steel plate and frame filter is made of stainless steel with high temperature resistance. The internal and external surfaces are polished with sanitary grade. The plate and frame is sealed without dripping and leakage, and the channel is smooth without dead angle, which ensures the effect of filtration, cleaning and sterilization. The sealing ring of medical and health grade can be used to clamp various thin and thick filter materials, and it is more suitable for the heat filtration of high temperature liquid materials such as beer, red wine, beverage, medicine, syrup, gelatin, tea beverage, grease, etc.

Features

The frame filter is suitable for industries such as biological products, medicine, brewing, food and beverage, tobacco, water treatment, petrochemical, environmental protection, etc., for precision filtration, clarification sterilization, purification treatment, etc. It can also filter the injection, infusion and other liquids in the pharmaceutical industry with good performance. The filter can also filter by means of a filter layer formed by a primary filter layer or a filter aid (for example, diatomaceous earth, clay, activated carbon, etc.) to obtain a clean liquid. According to the different filtration accuracy (crude filtration, fine filtration) requirements of the filtrate, customers can choose different filter materials for different filtration precision; and increase or decrease the number of layers of filter plates according to the production volume.

The filter has the advantages of less filtrate loss, large circulation, simple operation, convenient disassembly and assembly, and easy cleaning. The filter plate adopts a special structure of a flat threaded mesh shape, which is smooth and flat, and the filter material (filter cloth, filter paper, filter membrane) is not easily damaged, and can effectively prolong the service life of various filter materials, thereby reducing the production cost. The filter is equipped with a stainless steel pump, which has low motor power and low power consumption. The rubber wheel is mounted under the frame for flexible movement and light weight.

Structure

Four corners of each filter plate of the frame filter have four liquid-passing corner holes, and only the two vertical corner holes are communicated with the inside, and the filter plate and the filter frame are alternately arranged (the filter plate is double-sided hole plate, filter frame is non-porous plate). During filtration, media is fed through two liquid-passage holes on one side of the filter frame. After passing through the filter layer (filter media), the clear liquid is discharged from the two liquid outlet corner holes on the filter plate side.

Working Principle

This machine is a stainless steel multilayer frame filter press. It is suitable for the closed filtration of liquids with a concentration less than 50%, low viscosity, and low slag content to achieve the effects of fine filtration, decarbonization, and semi-fine filtration. It uses microporous membranes directly for sterile filtration. This machine has a large filtration area, large flow, and a wide range of applications, so it is widely used in pharmaceutical, chemical, food and other industries, especially for pharmaceutical injections, liquid filtration, the effect is very good.

The design idea of the plate-type filter was inspired by the cardboard filter, and this filter is fine manufactured after innovation and improvement. The product has a novel appearance and practicality. It can fit various kinds of filter materials such as filter cloth, filter paper board, filter film, etc. It can meet the requirements of different precision, grades and filtration processes of many kinds of liquids.

Two inlet and outlet connecting pipes are used for the inlet and outlet ports, which greatly increase the flow rate and ensure that it is pressed evenly during operation. Two glass sights can visually observe the difference of liquids between pre-filtration and post-filtration; the pressure gauge above the feed inlet clearly shows the state of working pressure during filtration; the sampling valve above the discharge port can not only facilitate the sampling of liquid material after filtration, but also can be used to perform deflation and emptying operation at the time of turning on and shutting down the filter. but also can be used for deflation and discharge when turning on and turning off the machine. The tri-clamp connector is very convenient for installation and removal. The matching valve and fittings conform to ISO and other health standards and they are exquisitely manufactured and can be integrated with the pipelines in the workshop.

You Might Also Like

Send Inquiry Our expert salesman will get back to you within 24hours!!!