high shear powder mixer

A high shear mixer is an ideal tool for powder blending because it can quickly and thoroughly blend powders of all different types and sizes

Product description

Video

Description

High shear powder mixers offer many advantages over traditional mixing methods. They can achieve a more homogeneous mix with less clumping and better distribution of powder throughout the mixture. In addition, high-shear mixers are much faster than traditional mixers and can often be used with smaller batches. This makes them ideal for use in laboratories or pilot plants, where time is often of the essence. Finally, high shear mixers often generate less dust, making them more environmentally friendly.

It has multiple functions, such as mixing, stirring, dispersing, homogenizing, emulsifying, etc., and has strong versatility. It has stable and uniform performance and is especially suitable for producing dairy products, beverages, food, and medicines. No powder, no particles, no clump formation. Modular structure: Direct use without on-site installation and commissioning, significantly reducing installation costs—compact design: small space occupation, easy to integrate with other systems, saving investment.

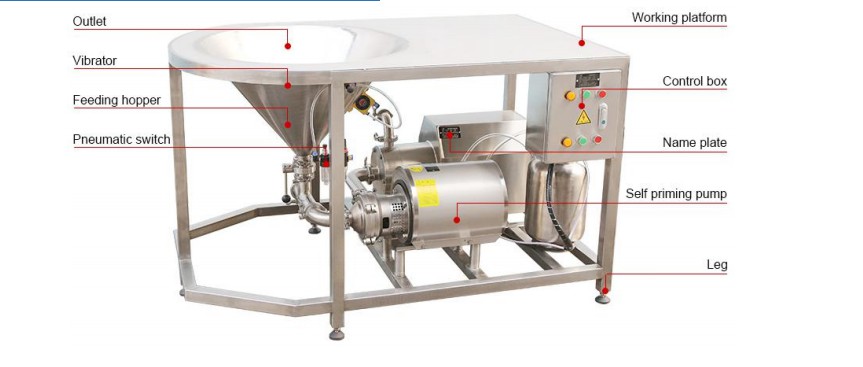

System workbench: Optional material is stainless steel SUS304 or 316L. The entire equipment system is relatively closed, clean, hygienic, safe, and easy to operate.

Dry powder feeder: It is a V-shaped feed port used to add dry powder solids, with an adjustable sanitary valve, and the control method is manual or pneumatic.

Sight glass: (optional): It is convenient for the operator to observe the working condition of the entire system visually.

Emptying system (optional): used for cleaning, emptying, and sampling.

High-efficient mixer: It is the core functional component of the system. The cleverly designed, precise, and the tightly engaged rotor-stator system makes the high-efficiency online mixer possess a variety of unique and mutually unified functions. They rotate at a high relative speed with each other at high speed and do not directly contact each other to avoid wear. It refers to the structure of a sanitary centrifugal pump. The pump shaft, mechanical seal, and seal ring are high-quality materials. Through high-precision CNC machining, the rotor, stator, and cavity are all made of integral forged stainless steel. The system is stable, efficient, safe, and reliable.

High-efficient power system: The powerful liquid ring vacuum power system is essential to ensure the system is efficient, stable, strong, and safe. The powerful hygienic liquid ring vacuum self-priming system provides conveying force for the entire mixer system and power for solid materials. It adopts stainless steel mechanical seal, which is durable, stable, and reliable.

Safety protection system: The system is equipped with a stainless steel double filter protection system to prevent any solid metal particles (nuts, welding slag, metal pieces, sand, etc.) from damaging the system.

Operating system: The system is designed reasonably, with a single button to start or stop operation, and faults are indicated separately. Simple operation and convenient maintenance. It has protection functions such as anti-overload, anti-short circuit, anti-phase loss, and interlocking interaction to prevent misoperation. It can also be equipped with a fully automatic operating system according to customer needs.

You Might Also Like

Send Inquiry Our expert salesman will get back to you within 24hours!!!