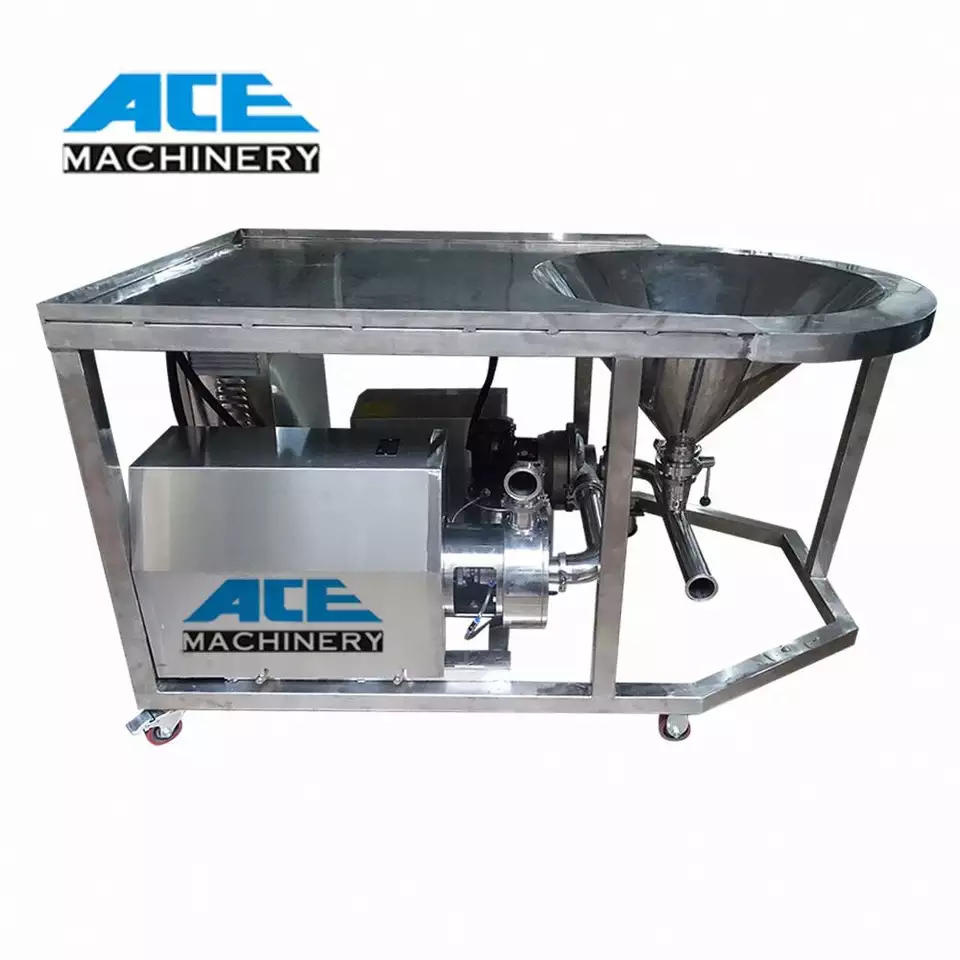

Lifting High Speed Disperser

High speed disperser is a high shear disperser system for the production of viscous dispersion in the cosmetic, pharmaceutical, food and chemical industries

Product description

Video

Description

High speed disperser is a high shear disperser system for the production of viscous dispersion in the cosmetic, pharmaceutical, food and chemical industries.

It’s especially suitable for wet dispersing and mixing solids in liquids. High-speed disperser is an important part of multi-shaft mixer.

High Speed Disperser Key Features

Working capacity from 1.5kw to 75kw;

Complete process of mixing, dispersing, shearing, emulsifying and homogenizing;

Suitable for solid liquid and liquid dispersion above 20,000cps viscosity;

Disperser dips down with a slight angle to avoid liquid swirling and for better dispersing;

Suitable for batch process with high efficiency;

Pneumatic or hydraulic lifting system for easy cleaning and maintenance;

Work with different mixing tanks;

All contact parts are made of SS304/316L and mirror polished;

Portable with castor wheels;

The specifications of the top entry batch mixer comply with GMP regulations;

Power supply of 380V, 50Hz, 3 Phase;

Mixer Options

High speed disperser can be replaced with batch homogenizer or propeller;

Different combinations of disperser, agitator, batch homogenizer and inline homogenizer for different processes;

Top, bottom or side mounted batch disperser available accordingly to different requirements;

Different hydraulic and electrical lifting devices for lifting the batch disperser for exchangeable tanks;

Adjustable brackets for holding the manufacturing tanks tightly;

Control panel with variable speed drive for adjusting homogenizing speed;

Explosion proof motors and electrics;

Different power supply acceptable;

High Speed Disperser: General Applications

Cosmetics & Toiletries: cream, lotion, wax, mascara, gel, toothpaste;

Pharmaceuticals: ointment, dental composite, syrup, injection;

Food: mayonnaise, dressing, jam, butter, margarine, wasabi;

Chemicals: polyester, synthetic fiber, shoe cream;

You Might Also Like

Send Inquiry Our expert salesman will get back to you within 24hours!!!