inline high shear mixer

Inline High-shear Emulsifier is a continuous production type emulsifier with high efficiency It processes materials in continuous production or ci...

Product description

Description

Inline High-shear Emulsifier is a continuous production type emulsifier with high efficiency. It processes materials in continuous production or circulation of fine materials. The motor drives the rotor to rotate at high speed. Widely used in food and beverage, ink, paper, adhesives, lubricants, pesticides, cosmetics, pharmaceuticals.

Material viscosity: <=10,000 cps

Production Capacity: 1000L-80000L/hour

Applied materials: suitable for emulsifying, homogenizing and dispersing materials in industries, such as biology, pharmacy, food, cosmetic, ink and pesticides etc.

INTRODUCTION:

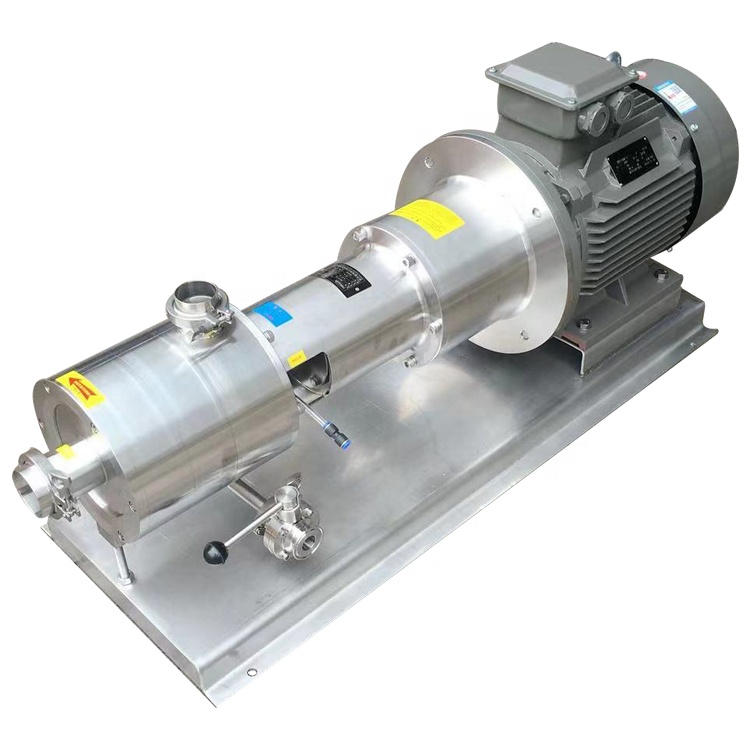

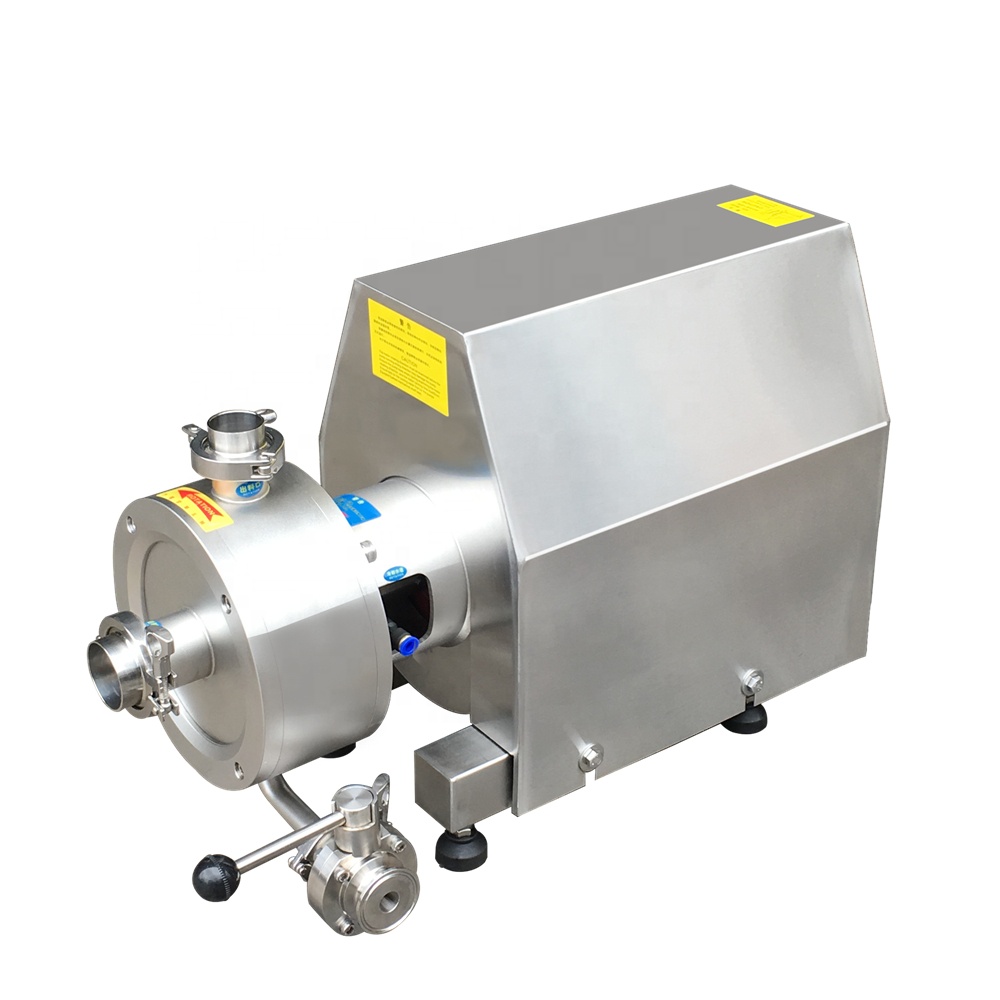

Inline Emulsifier Mixer is a high shear mixer for inline or continuous operation. In the Inline process, the mixer is installed outside the tank. This makes it easy to be built into an existing production line with normal inlet/outlet connections.

In the case to deal with liquid with a low viscosity, the inline mixer can pump the liquid without an additional pump. That is why it is also called High Shear Pump.

The mixer can be used to deal with the product in a single pass or with several circulations to make the product better.

Different from a Batch High Shear Mixer, the mixing occurs in the mixing chamber, thus energy is introduced onto materials in the most efficient way. This also cuts the process times by up to 90%

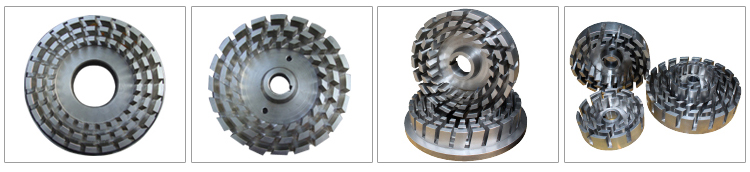

Stator/Rotor Type

● Narrow particle size distribution, high uniformity

● With short distance, low lift transmission function

● Elimination of quality differences between batches

● Time-saving, high-efficiency, energy-saving

● Low noise and stable operation

● Easy to use, easy to maintain

● can achieve automatic control

● No dead ends, the material 100% pass through and is dispersed and sheared

Feature:

Capacity

Self-pumping throughputs of 1000 to 80,000 litres/hr.

No Bypassing

Product cannot bypass the precision rotor/stator workhead.

Interchangeable Workheads

Three stages rotor/stator configurations workheads as standard. For the rotor/stators configurations, 2,4 and 6 layers structures makes the best shearing result.

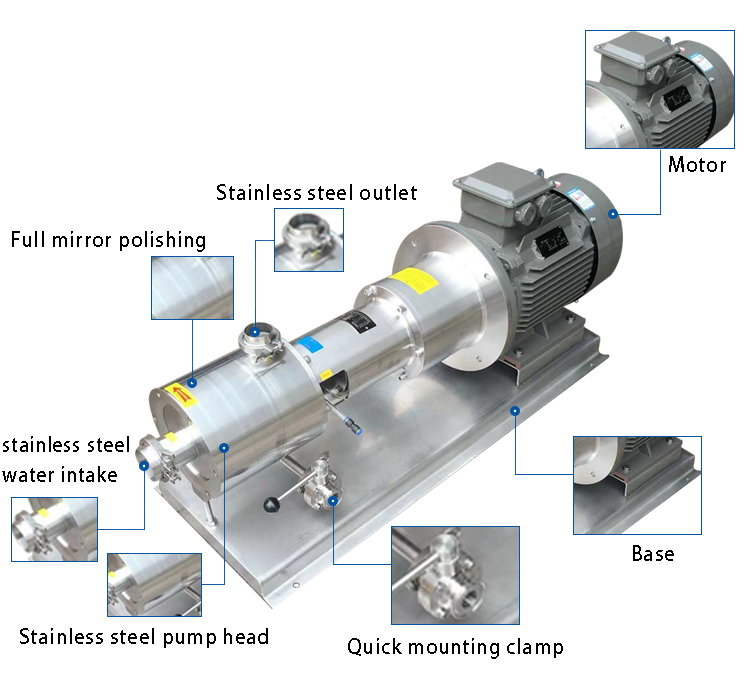

Materials of Construction

Product contact in SS304 or 316L stainless steel.

Motor Specification

Standard and explosion proof motors (Siemens ,ABB etc) are available as standard.

Inlet and Outlet Connections

All sanitary screw or flange fittings available on request (e.g. ISS, D/N, RJT, SMS, Tri-clamp, etc.).

Sealing

Single or double mechanical shaft seals available as standard.

Cooling

Cooling jacket structure as standard

| Model | Power(kw) | Speed(RPM) | Capacity (1000L/Hour) |

| BRL1-60 | 1.5 | 2800 | 0-1.5 |

| BRL1-100 | 2.2 | 2800 | 0-3 |

| BRL1-130 | 4 | 2800 | 0-4 |

| BRL1-140 | 5.5 | 2800 | 0-5 |

| BRL1-165 | 7.5 | 2800 | 0-8 |

| BRL1-180 | 11 | 2800 | 0-12 |

| BRL1-185 | 15 | 2800 | 0-18 |

| BRL1-200 | 22 | 2800 | 0-25 |

| BRL1-210 | 30 | 2800 | 0-35 |

| BRL1-230 | 45 | 2800 | 0-50 |

| BRL1-245 | 55 | 2800 | 0-75 |

| BRL1-260 | 75 | 2800 | 0-90 |

| BRL1-275 | 90 | 2800 | 0-110 |

| BRL1-280 | 132 | 2800 | 0-130 |

You Might Also Like

Send Inquiry Our expert salesman will get back to you within 24hours!!!