What is the difference between Lobe pump and screw pump

View:

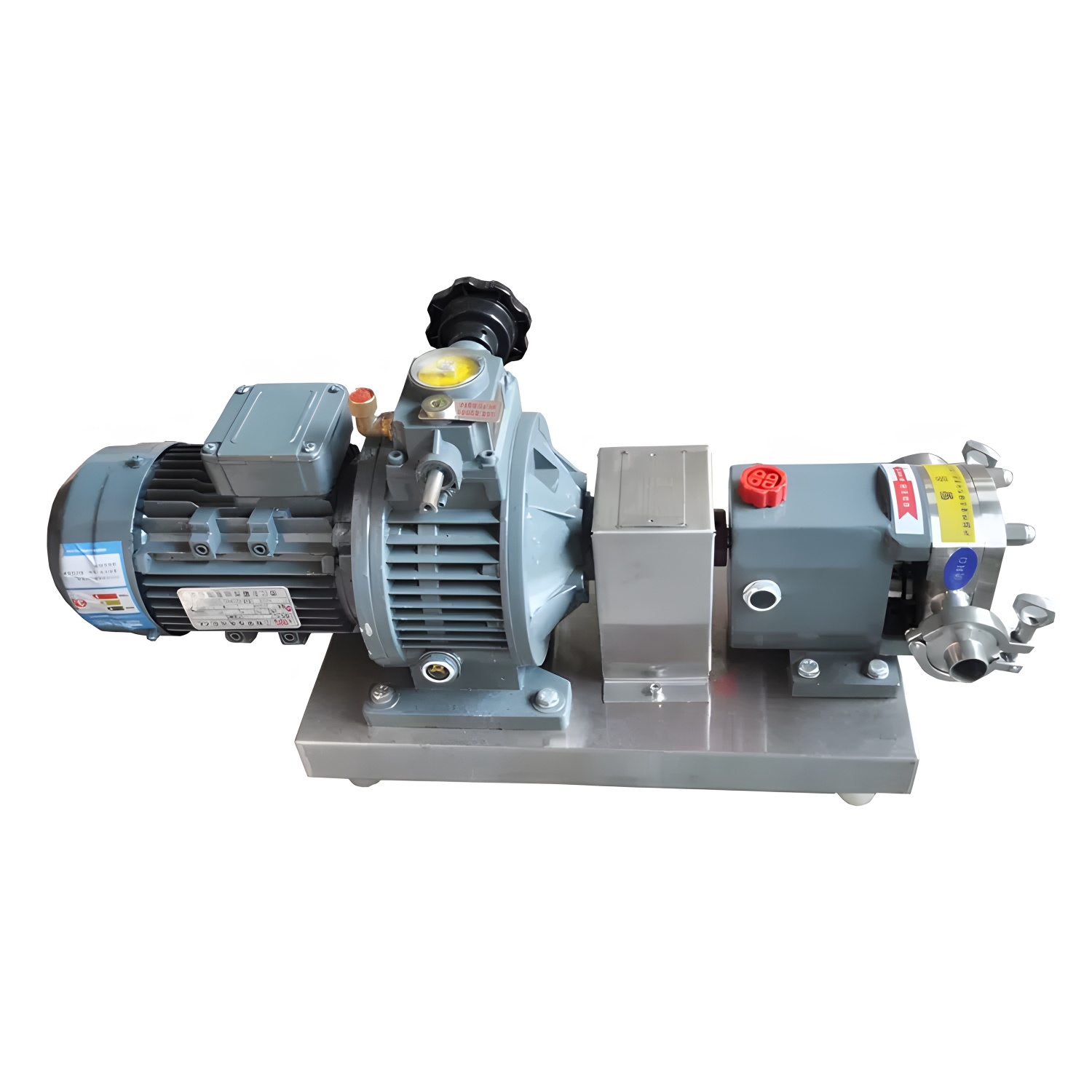

The lobe pump and screw pump both belong to the same volume pump, and their performance is similar - both can smoothly transport high viscosity substances and have a high transfer pressure. So, what are the differences between the Lobe pump and the screw pump?

The difference between Lobe pumps and screw pumps.

1, the internal structure is different. The lobe pump is through the two Lobes in the pump cavity reverse rotation, the volume of the inlet to the delivery port from large to small to achieve the purpose of conveying materials, while the screw pump is through the spiral screw in the rubber stator rotation, so that the material from front to the back of the screw rotation eventually sent from the discharge port.

2, the difference in the life of accessories. Because there is no friction between the Lobe pump parts, the Lobe pump wear parts have a long service life; the wear on the overflow parts is mainly from the abrasive and corrosive components in the medium; In contrast, the screw pumps friction between the Lobe and stator, the medium particles, etc. at the same time affect the service life of the wear parts. Eccentric rotation of the Lobe is generated by the stator's stress, which intensifies the wear between the legs. Even if the medium is transported without any particles, the stator of the pump will gradually wear.

3, the sanitation level is different. Due to the non-streamlined surface of the screw pump and the numerous defects in the chamber, it is impossible to become a sanitary pump. Damage to the cavity wall tetrafluoro or rubber is more likely to cause contamination of the conveyed medium. In contrast, the Lobe pump, due to the streamlined structure of the Lobe and the essential absence of dead spots and non-metallic parts in the Lobe chamber, so high viscosity volume pump is more suitable for application in food and beverage, pharmaceutical, and other industries with high sanitary requirements, especially nowadays, the production line automation is getting higher and higher. At the same time, more and more online cleaning is used, which shows the importance of choosing a lobe Lobe pump. Therefore, the Lobe pump hygiene level is higher than the screw pump.

4 、Different conveying directions. The lobe pump conveying direction can be reversed; the pump is a completely symmetrical structure; while the screw pump can not be changed, the seal is under pressure at the time of reverse conveying.

5, self-priming capacity is different. Screw pump has an excellent self-priming ability, but to avoid pump idling, and can not exceed 30 seconds; Lobe pump, in the case of speed greater than 200rpm, can produce an excellent self-priming ability.