What is milk cooling tank?

View:

The milk cooling tank is an important piece of equipment for mechanised milking on farms and is more suitable for cooling and storing fresh milk in hand dispersed milking farms and collection stations and dairies.

1、 Use and structure

The product has a beautiful shape, compact structure, high degree of automation and small footprint. It can save energy and keep milk fresh at low temperature for a long time. The refrigeration performance level is in accordance with ISO5708-1983AII to ensure the high quality of milk.

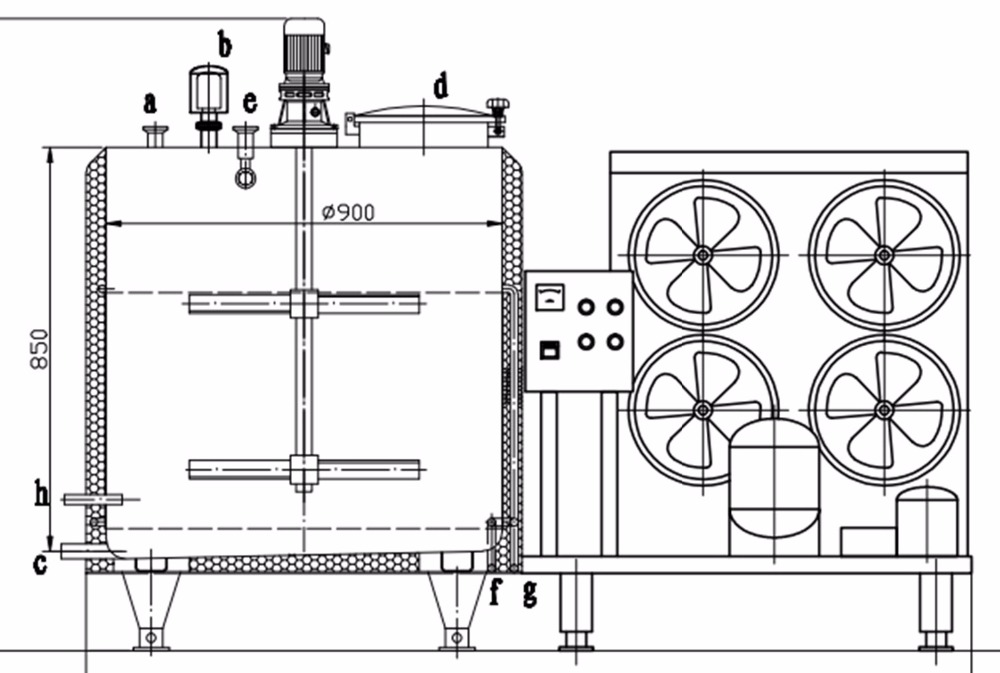

The milk cooling tank consists of five main parts: tank, mixer, scrubber, refrigeration unit and electrical control box.

The milk tank is a horizontal oval body with polyurethane rigid foam board between the inner and outer tank, which has a thermal insulation layer with low thermal conductivity, light specific gravity, high strength and low water absorption, and good insulation performance. The tank wall adopts an advanced plate evaporator to directly exchange heat with the milk for refrigeration. The refrigeration compressor adopts the TAGZ4573THR type compressor produced by TLCUMSEH (Taikang) imported from France, and is equipped with a reliable mid-point protector, which will not burn out the motor due to overload or system failure. The product is designed and manufactured with advanced technology and reliable performance. The cooling and insulation performance and hygiene standards are in line with international advanced level.

2、 Performance and characteristics

milk cooling tank is made of imported or high quality SUS304 stainless steel. It is both clean and hygienic, and corrosion resistant, and is precision polished so that dirt should not accumulate.

The two refrigeration plates are controlled by two sets of refrigeration compressor sets, which can work separately or simultaneously to ensure fast and even cooling of milk without icing. As the insulation layer is filled with rigid foam material with low thermal conductivity, it is light in weight and has excellent insulation performance.

3. Controllable and storage

The direct-cooled milk storage tank is fully automatic and the electrical control box can be installed on the side or near the end of the tank for easy automatic control. The combination of the tank equipment and the electrical control box enables automatic temperature control of the refrigeration system. The compressor is protected against high pressure faults and motor overload (2.0MPa for high pressure protection and 0.2MPa for low pressure stop). When the milk tank needs to be pre-cooled, the machine can be switched on manually. The stirring motor works synchronously with the compressor. When the compressor stops working, if required, the stirring switch can be turned to automatic, at which point the stirrer will enter an adjustable intermittent rotation.

When storing milk for a long time, if the temperature of the milk in the tank is higher than 6 ℃ (adjustable), the compressor will start itself and carry out cooling until the temperature of the milk in the tank drops below 4 ℃ (adjustable) when it stops automatically, thus achieving the purpose of keeping the milk cold.

Installation requirements

A. Handling of equipment: milk cans and refrigeration units are generally packaged separately. During transportation, pay attention to damage, lifting and handling with care. At the same time, the handling route and the door size of the machine room shall be considered. When the equipment arrives, check whether the box is damaged before unpacking, verify the box number and quantity, and pay attention not to damage the parts when unpacking.

B. Location requirements of the house: the total area of the milk tank machine room shall not be less than 40 square meters, and the air circulation of the machine room shall be maintained. The position of the milk tank in the machine room must ensure that the pipe box of the milk tank is 1m away from the refrigeration unit.