What is a sanitary emulsification pump?

View:

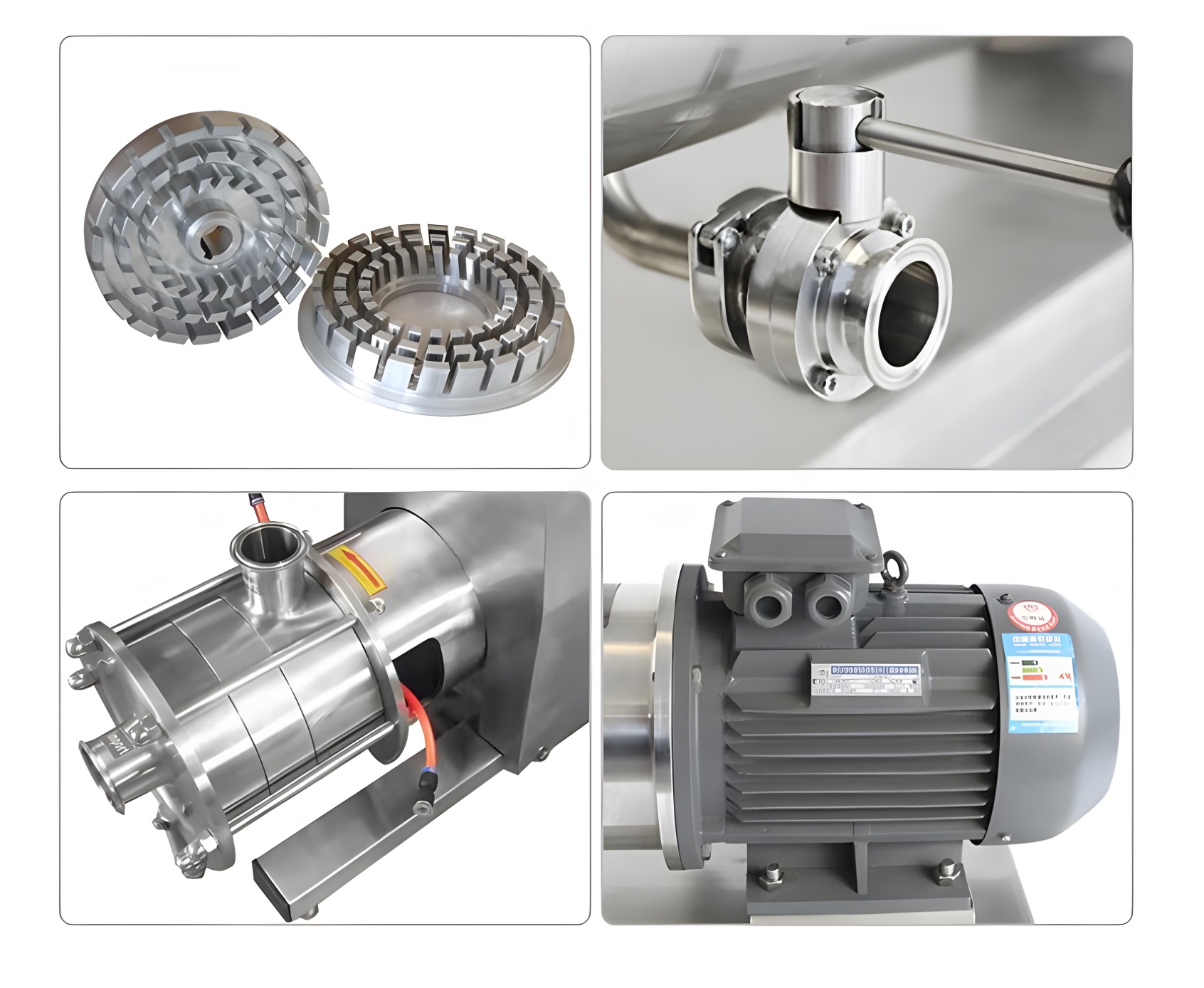

A Sanitary emulsification pump is high-performance equipment for continuous production or recycling of fine materials, widely used in food, pharmaceutical, chemical, and other industries, where the food and pharmaceutical industries have higher sanitary requirements for emulsification pumps. The working principle of a clean emulsification pump is that the material is sucked in through the inlet, sheared, squeezed, and homogenized under the rotor speed of 2800 rpm, and then discharged from the outlet after the material is thoroughly homogenized and emulsified to achieve the purpose of mixing, crushing and emulsification. The basic structure of the sanitary emulsification pump is composed of a motor, spindle, stator and rotor, shell, base, inlet, and outlet. Sanitary emulsification pump is clean equipment parts surface are polished, contact material using 304 or 316L stainless steel materials, import and export for by any fast connection, can comply with GMP norms, to ensure the safety of materials, health. So, what sanitary emulsification pump needs to meet the hygienic requirements?

Emulsification pump

The Sanitary emulsification pump needs to meet the following sanitary requirements.

1, the pump body and material contact parts are used 304, 316 stainless steel or other materials that will not react with the material and cause contamination to the material.

2, the pump body in the material production will not have leaks or debris mixed into the situation.

3, there is basically no, or no material quickly left inside the pump body, so it is not easy to clean the parts.

4, easy to use, easy to maintain.

5, the pump body runs smoothly and reduces the difference in mass production quality as much as possible. The Sanitary emulsification pump fully meets food equipment requirements and can be used confidently in food, pharmaceutical, fine chemical, and other places with high sanitary conditions. Hengdong clean emulsification pump has a large capacity, handles a broader range of viscosity, has no batch-to-batch production quality differences, has a low head conveying function, low noise, smooth operation, high efficiency, and can pass through the working chamber, etc.