What Is Magnetic Mixing tank

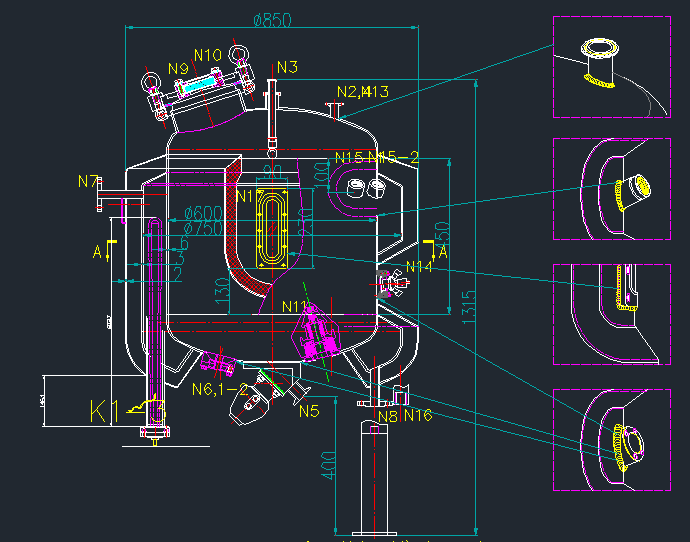

View:

Magnetic Mixing tank, also known as batching tank, mixing tank, batching barrel, mainly used for milk and sugar and other elements and the name of the red stuff in conjunction with the role of mixing evenly after. The public cylinder body, cylinder cover, stirring pulp, inlet and outlet valve are made of stainless acid resistant steel 1Cr18Ni9Ti, according to GB741-80 technical condition, the cylinder body is polished inside and outside, there is stirring pulp inside, which plays the role of stirring, there is a thermometer on the top, which shows the temperature inside the cylinder, there is a cycloid planetary reducer on the top, which drives the stirring pulp and can be assembled and disassembled and cleaned. There are two openable cylinder covers for cleaning, and two feeding ports, which can be connected with pipeline to facilitate the connection of various ingredients, and the following has a discharge port, and installed with a plug, etc. After stirring evenly, rotate the plug valve handle 90 degrees to release the material, and can be closed when the material is released, to achieve the purpose of mixing evenly.

Use

1. Can be used as liquid storage tank, mixing tank, temporary storage tank, water storage tank, etc.

2. Suitable for food, dairy products, juice and beverage, pharmaceutical and chemical industry and biological engineering fields.

Structure Description

Stirring tank: magnetic stirring tank electric heating stirring tank stainless steel stirring tank

Sandwich heating: heating method is divided into electric heating, steam heating

Outer insulation layer according to the requirements of the container sealing design flange head and lift-off cover design to consider heating control Stirring power

Structural features of the mixing tank.

1. Single-layer stainless steel structure is used.

2. Materials are sanitary stainless steel.

3. Structure design is very humane and operable.

4. The transition section of the cylinder body wall adopts circular arc transition to ensure hygiene without dead ends.

Configuration

1. Quick-open manhole.

2. Various shapes of CIP cleaners.

3. Anti-fly and insect sanitary breathable cover.

4. Adjustable triangular legs.

5. Removable feeding tube kit.

6. Thermometer (according to customer's requirements)

7. Climbing ladder (according to customer's requirements).

8. Paddle stirrer.

9. Liquid level meter and level control (according to customer's requirements).

10. Anti-vortex plate.

Maintenance of the machine

1、The bearing bears all the load of the machine, so good lubrication has a great bearing life, it directly affects the service life of the machine and running rate, thus requiring the injection of lubricant must be clean, the seal must be good, the main oiling place of this machine (1) rotating bearings (2) roller bearings (3) all gears (4) active bearings, sliding plane.

2, the newly installed wheel hoop is prone to loosening must be checked frequently.

3, pay attention to the work of the machine parts are normal.

4, pay attention to check the degree of wear and tear of easy-to-wear parts, always pay attention to the replacement of worn parts.

5, put the active device of the bottom shelf plane, should go out of dust and other things so that the machine can not crush the material when the active bearing can not move on the bottom shelf, resulting in serious accidents.

6、The bearing oil temperature rises, should immediately stop to check the cause to eliminate.

7、If there is an impact sound when the rotating gear is running, stop immediately to check and eliminate